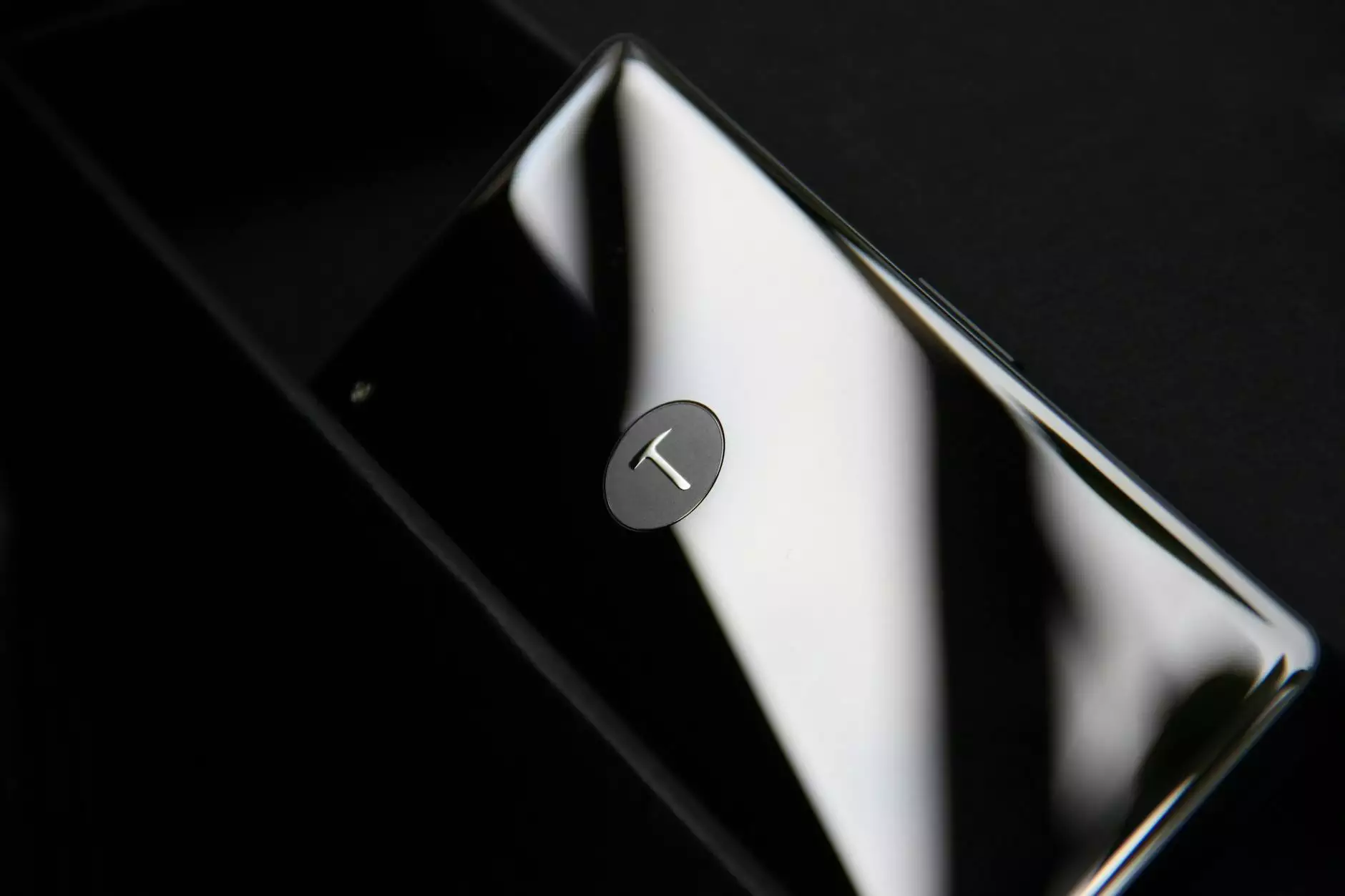

The Power of Low Cost Laser Marking Machine for Metal Fabricators

In the world of Metal Fabricators, the need for precision, efficiency, and cost-effectiveness is paramount. One technology that has revolutionized the industry is the low cost laser marking machine. By incorporating this cutting-edge tool into their processes, Metal Fabricators can unlock a multitude of benefits that can propel their business to new heights.

Enhanced Precision and Versatility

Low cost laser marking machines offer unparalleled precision in marking various materials including metals. The focused laser beams ensure that the markings are clear, crisp, and permanent, even on the smallest of components. This level of precision is essential for Metal Fabricators who deal with intricate designs and detailed specifications.

Efficiency and Productivity

By implementing a low cost laser marking machine, Metal Fabricators can significantly boost their efficiency and productivity. These machines operate at high speeds, allowing for quick and precise marking of parts and components. This not only saves time but also reduces the margin of error, leading to fewer reworks and increased overall output.

Cost-Effectiveness

Contrary to common belief, low cost laser marking machines are not only efficient but also cost-effective. The initial investment in this technology pays off in the long run as it reduces the need for consumables and maintenance costs associated with traditional marking methods. Metal Fabricators can enjoy a high return on investment by switching to laser marking.

Quality Assurance and Traceability

With laser marking, Metal Fabricators can ensure quality assurance and traceability of their products. The permanent markings created by the laser are resistant to wear, ensuring that vital information like serial numbers, part codes, and logos remain intact throughout the product lifecycle. This level of traceability is crucial for compliance and customer satisfaction.

Environmental Friendliness

Another advantage of low cost laser marking machines is their environmental friendliness. Unlike traditional marking methods that use chemicals and inks, laser marking is a non-contact, non-toxic process that produces no waste. Metal Fabricators can reduce their environmental footprint while maintaining high standards of quality.

Conclusion

In conclusion, the adoption of a low cost laser marking machine can bring a plethora of benefits to Metal Fabricators, from enhanced precision and efficiency to cost-effectiveness and environmental friendliness. By leveraging this cutting-edge technology, businesses can stay ahead of the competition and meet the demanding requirements of the industry.

For Metal Fabricators looking to optimize their marking processes, investing in a low cost laser marking machine is a strategic decision that can yield both immediate and long-term advantages.